We undertake Chemical cleaning of Boilers, Heat Exchangers, Tanks, Pipelines, & Industrial Equipments Projects • Degreasing • Descaling • Neutralization • Passivation

Services

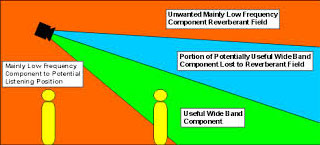

The objective is to specify the equipment requirements for a sound system used to assist in the safe evacuation of building occupants in the event of a fire alarm or other emergency. It includes Area of coverage - Loudspeaker zone – Information – Audibility – Intelligibility – Clarity – Alarm – Warning – Danger – Emergency - Emergency zone - Critical signal path - Emergency Detection system - Voice alarm system The purpose of this is to specify the performance requirements for sound systems which are primarily intended to broadcast information for the protection of lives within one or more specified areas in an emergency.

The purpose is to be understood when assessing accuracy (trueness and precision) of measurement methods and results, and in applications, and to establish practical estimations of the various measures by experiment. Is concerned exclusively with measurement methods which yield measurements on a continuous scale and give a single value as the test result. May be applied to a very wide range of materials, including liquids, powders and solid objects,

Valuation of plant and machinery is highly complex in nature as our practice caters to a wide spectrum of industries each having plant and machinery with its own inherent characteristics.Among the issues to be considered in the valuation of plant and machinery are the specific utility or usefulness of industrial property, its contribution to the production of goods and services for which it is designed and deployed. It also covers estimation in monetary terms the worth of the plant and machinery in existing use or their contribution to the profitability of the business after considering the market situation or standard of maintenance.

Manual material handling ranges from movement of raw material, work in progress, finished goods, rejected, scraps, packing material, etc. These materials are of different shape and sizes as well as weight. Material handling is a systematic and scientific method of moving, packing and storing of material in appropriate and suitable location. The main objectives of material handling are as follows: It should be able determine appropriate distance to be covered. Facilitate the reduction in material damage as to improve quality. Reducing overall manufacturing time by designing efficient material movement Improve material flow control Creation and encouragement of safe and hazard-free work condition Improve productivity and efficiency Better utilization of time and equipment It is critical for manufacturing organization to identify importance of material handling principle as the critical step in promoting the job improvement process. In the current competitive and globalized environment, it is important to control cost and reduce time in material handling. An efficient material handling process promotes: Design of proper facility layout Promotes development of method which improves and simplifies the work process It improves overall production activity. Efficient material handling reduces total cost of production.

Vibration monitoring and analysis in rotating machinery offer very important information about anomalies formed in the internal structure of the machinery. We also do Condition monitoring of rolling element bearings by vibration analysis, and Damage identification and health of structural and mechanical systems from changes in their vibration characteristics. Our expertise lies in application of signal processing techniques to machinery health monitoring.

Acoustic monitoring is being used by researchers and agencies to asses populations, guide policy, and monitor effects of human noise on wildlife. Effects of noise on wildlife. Some species affected at audibility near ambient Others seemingly more adaptable resilient

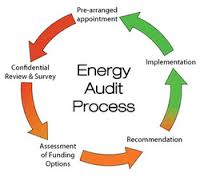

Within the framework of the Energy Conservation Act, 2001 there is a provision to introduce energy auditors. Responsibilities of Energy Auditors 1.Prepare an annual activity plan and present to management concerning financially attractive investments to reduce energy costs. 2.Establish an energy conservation cell within the firm with management’s consent about the mandate and task of the cell. 3.Initiate activities to improve monitoring and process control to reduce energy costs. 4.Analyze equipment performance with respect to energy efficiency. 5.Ensure proper functioning and calibration of instrumentation required to assess level of energy consumption directly or indirectly. 6.Prepare information material and conduct internal workshops about the topic for other staff. 7.Improve dis-aggregating of energy consumption data down to shop level or profit center of a firm. 8.Establish a methodology how to accurately calculate the specific energy consumption of various products/services or activity of the firm. 9.Develop and manage training program for energy efficiency at operating levels. 10.Co-ordinate nomination of management personnel to external programs. 11.Create knowledge bank on sectoral, national and international development on energy efficiency technology and management system and information denomination. 12.Develop integrated system of energy efficiency and environmental up-gradation, Wide internal & external networking. 13.Co-ordinate implementation of energy audit/efficiency improvement projects through external agencies. 14.Establish and/or participate in information exchange with other energy managers of the same sector through association.